The Growing Need for Precision in Chip Manufacturing

The semiconductor industry is facing unprecedented challenges. The demand for ever-smaller, more powerful, and energy-efficient chips is skyrocketing, driven by the proliferation of smartphones, AI applications, and the Internet of Things. Meeting this demand requires an incredible level of precision and efficiency in the manufacturing process. Even microscopic imperfections can render a chip unusable, resulting in significant financial losses. This is where robots are stepping in to revolutionize the game.

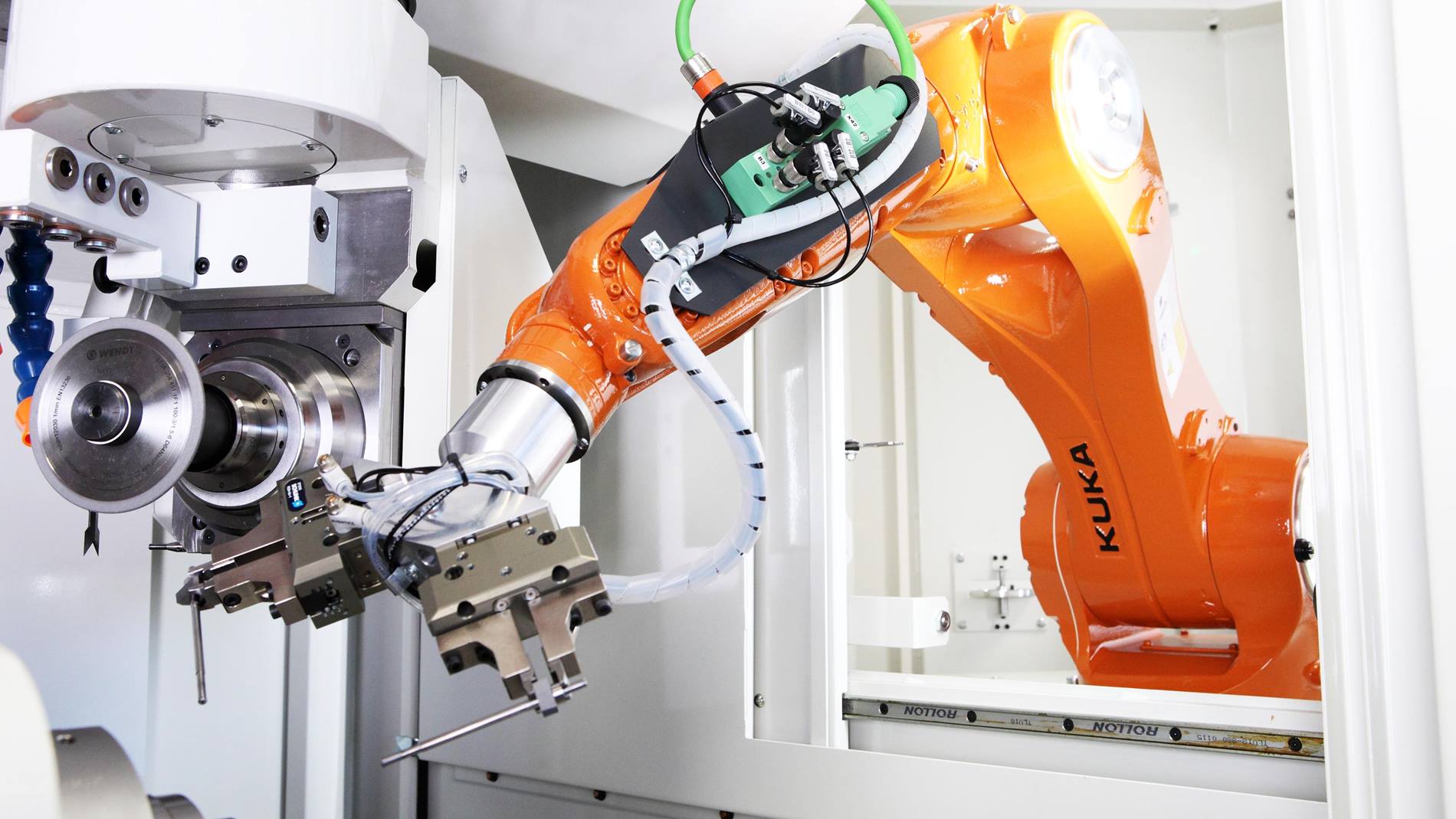

Robots Offer Unmatched Precision and Repeatability

Human hands, even with the aid of sophisticated microscopes and tools, simply cannot achieve the level of precision required for modern chip manufacturing. Robots, on the other hand, excel at repetitive tasks with unwavering accuracy. They can perform intricate maneuvers with micron-level precision, placing components with pinpoint accuracy and consistently applying the necessary pressure and force. This ensures uniformity across millions of chips, significantly reducing defects and improving yield.

![]()

Automated Material Handling and Wafer Processing

Robots are playing a crucial role in automating various stages of chip manufacturing. They handle delicate silicon wafers with utmost care, moving them between different processing stations without risk of damage. This automation reduces the chance of human error and significantly speeds up the overall manufacturing process. From loading and unloading wafers to transferring them through etching, deposition, and lithography processes, robots are ensuring smooth and efficient operations.

Enhanced Safety in Hazardous Environments

Chip manufacturing involves exposure to hazardous chemicals and materials. Robots can operate safely in these environments, shielding human workers from potential health risks. This is especially important in cleanroom environments where even the smallest particle of dust can compromise the integrity of a chip. By automating these hazardous tasks, companies can prioritize the safety and well-being of their employees.

Increased Throughput and Reduced Production Time

The speed and efficiency of robots contribute to a significant increase in chip production throughput. Unlike human workers who need breaks and are susceptible to fatigue, robots can operate continuously, maximizing production capacity. This faster production process reduces lead times, allowing companies to respond more quickly to market demands and stay ahead of the competition. The reduction in downtime also leads to significant cost savings.

Advanced Robotics and AI Integration for Enhanced Capabilities

The latest advancements in robotics and artificial intelligence are further enhancing the capabilities of robots in chip manufacturing. AI-powered vision systems allow robots to identify and correct defects in real-time, ensuring only perfect chips proceed to the next stage. Machine learning algorithms optimize robot movements and processes, continuously improving efficiency and reducing waste. This integration of advanced technologies is driving the next generation of chip manufacturing automation.

Addressing the Skill Gap and Workforce Development

While automation through robotics might initially raise concerns about job displacement, it also creates new opportunities in areas like robot programming, maintenance, and AI development. The semiconductor industry needs skilled professionals to manage and maintain these advanced robotic systems. This shift requires investment in workforce development programs that equip individuals with the necessary skills to thrive in this evolving landscape. The focus should be on retraining and upskilling existing workers, creating a more robust and adaptable workforce.

The Future of Chip Manufacturing: A Collaborative Human-Robot Partnership

The future of chip manufacturing is not about robots replacing humans, but rather about creating a collaborative partnership between the two. Human ingenuity and problem-solving skills remain crucial in designing, optimizing, and overseeing the complex manufacturing processes. Robots, in turn, provide the precision, speed, and safety necessary to meet the ever-increasing demands of the industry. This collaborative approach will unlock new levels of efficiency and innovation in chip manufacturing, driving the technological advancements that shape our world. Click here to learn about automation and robotics for semiconductors.